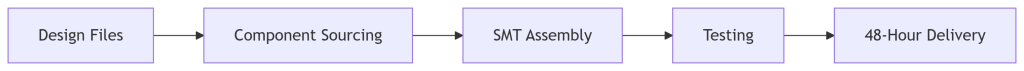

1. Rapid Prototyping Assembly

Accelerated Development Cycles

| Capability | Specification | Industry Comparison |

|---|---|---|

| Component Size | 01005 (0.4×0.2mm) | Standard: 0201 |

| Fine Pitch | 0.3mm BGA | Standard: 0.5mm |

| Turnaround | 24-48 hours | Standard: 5-7 days |

| First-Pass Yield | 99.2% | Industry: 95% |

Key Features:

- Real-time 3D SPI solder paste inspection

- Free DFM analysis with 4-hour response

- Functional test report with every prototype

2.High-Volume Production

| Quality Parameter | FlashPCBA Standard | Industry Benchmark |

|---|---|---|

| AOI Rejection Rate | <0.05% | 0.2-0.5% |

| ICT Failure Rate | 0.02% | 0.1-0.3% |

| DPPM (Defects Per Million) | <50 | 200-500 |

| Traceability | Component-level | Batch-level |

Manufacturing Infrastructure:

-

12 Yamaha high-speed SMT lines (98,000 CPH)

-

Automated optical inspection (10μm resolution)

-

X-ray inspection for BGA/QFN components

-

In-circuit and functional testing stations

3. Advanced Assembly Technologies

Specialized Processes for Complex Requirements

Complex Assembly Capabilities

| Technology | Application | Equipment |

|---|---|---|

| Mixed Technology | Through-hole + SMT | Selective soldering |

| Press-Fit Connectors | Automotive/Aerospace | Hydraulic press systems |

| Underfill & Epoxy | BGA/CSP components | Automated dispensing |

| Conformal Coating | Harsh environments | Robotic spraying |

| Box Build Assembly | Complete systems | Integration workstations |

Material Expertise:

-

Lead-free soldering (SAC305)

-

Low-temperature solders (SnBiAg)

-

MIL-spec conformal coatings (UL746E)

-

Thermally conductive adhesives

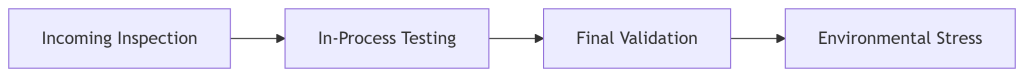

4. Testing & Validation Services

Comprehensive Quality Assurance

Testing Coverage Analysis

| Test Type | Coverage | Standards |

|---|---|---|

| Automated Optical (AOI) | 100% boards | IPC-A-610 |

| X-Ray Inspection | BGA/QFN components | IPC-7095 |

| In-Circuit Test (ICT) | 95% net coverage | IEEE 1149.1 |

| Functional Test (FCT) | System validation | Customer specs |

| Environmental Stress | Temp/Humidity/Vibration | MIL-STD-883 |

5. Industry-Specific Solutions

Tailored Manufacturing for Critical Applications

| Industry | Key Requirements | FlashPCBA Expertise | Certifications |

|---|---|---|---|

| Automotive | AEC-Q200 components Extended temp range Vibration resistance |

-12-layer ECU boards Heavy copper PCBs Conformal coating |

IATF 16949 IPC-6012DA |

| Medical | Biocompatible materials Class III reliability Hermetic sealing |

-Flex-rigid assemblies Micro-component placement Cleanroom assembly |

ISO 13485 FDA GMP |

| Aerospace | MIL-spec soldering High-reliability Extended lifecycle |

-Hi-rel components PTFE RF boards Conformal shielding |

AS9100D Nadcap |

| Industrial IoT | Wide temp range Power management Wireless connectivity |

-Embedded systems Power management RF design |

UL 508A CE/EMC |

6. Supply Chain Management

End-to-End Component Solutions

| Service | Capability | Benefit |

|---|---|---|

| Component Sourcing | 500+ certified suppliers | Cost optimization |

| Lifecycle Management | EOL/Obsolescence monitoring | Risk mitigation |

| Counterfeit Prevention | XRF/X-ray verification | Quality assurance |

| Consignment/VMI | Dedicated storage areas | Inventory reduction |

| Supply Chain Resilience | Multi-region sourcing | Continuity assurance |

7. Quality Certifications

Commitment to Excellence

Compliance Standards:

-

IPC-A-610 Class 3 Workmanship

-

IPC-J-STD-001 Soldering

-

ANSI/ESD S20.20 ESD Control

-

RoHS 3 / REACH Compliance

-

UL Recognition (File E522398)